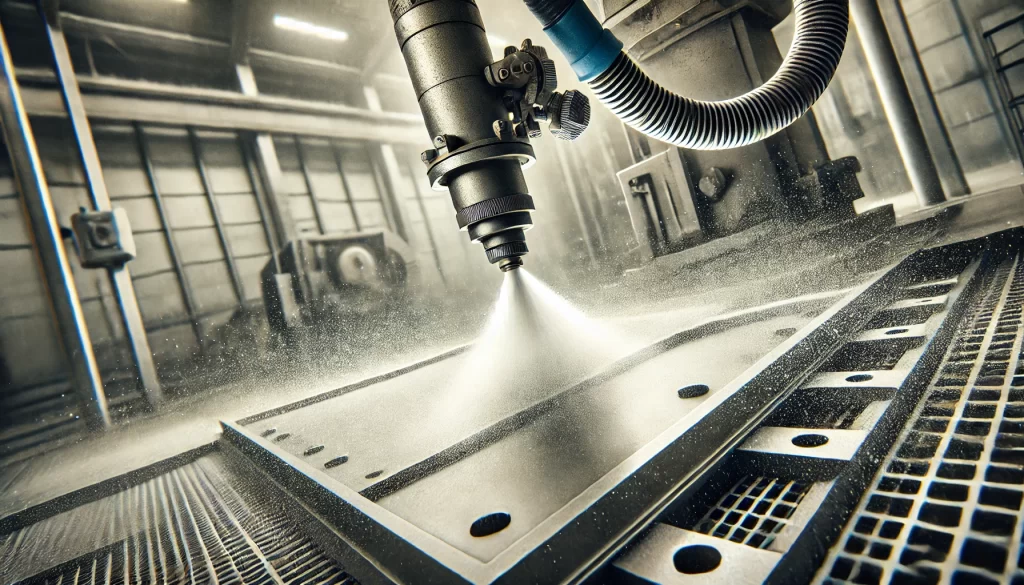

Shot-blasting is a surface treatment process used in industrial settings.

At Pershore Dip Coating, our shot blasting service effectively removes rust, paint, and other contaminants from metal and other hard surfaces, and can be used to create a smooth, uniform finish that’s ideal for coating or preparation.

Which industries use shot-blasting?

Shot-blasting is an essential treatment in a wide range of different sectors, including:

Automotive

Shot-blasting is a widely used process in the automotive sector for manufacturing and maintenance processes.

It’s used to prepare metal surfaces for painting, or coating, to ensure the finish is smooth and uniform. Car chassis and frames will undergo shot-blasting to remove rust, scale, and other contaminants.

High-pressure shot-blasting is also used to induce compressive stress on metal components, such as gear systems and springs, to increase their durability and overall fatigue resistance.

It’s also used as a technique to refurbish and restore worn vehicle parts, such as alloy wheels.

Aerospace

Shot-blasting is used in the aerospace sector for a variety of purposes, including surface preparation.

Aircraft components, like turbine blades and landing gear that can quickly build contaminants, are often shot-blasted before repairs or inspections.

Shot-blasting is also used to strengthen critical components, such as fuselage parts and engine turbines, to increase their resistance to cracking under stress and fatigue.

Construction

Shot-blasting removes dirt and coatings from concrete surfaces, creating a rough texture that allows for better bonding.

Metal beams, girders, and reinforcements used in construction projects will often be shot-blasted to remove scale and rust before fabrication or assembly.

Shot-blasting is also used to clean or roughen surfaces such as concrete floors, driveways, and pavements. This extends the surface’s lifespan and also improves slip resistance.

Steel

The steel industry is heavily reliant on shot-blasting for strengthening, finishing, and cleaning metal products.

It can remove the mill scale, rust, and other impurities from manufactured steel, and creates a uniform profile on steel surfaces. This is essential for subsequent treatments like galvanising, powder coating, or painting.

Shot-blasting can also be used to harden steel components, enhancing their structural integrity and making them more resistant to wear and tear.

Marine

Shot-blasting is deployed in the marine sector for the maintenance and refurbishments of vessels.

It’s most often used to remove barnacles, rust, and algae from the hulls of ships and marine propellers, tackling deterioration and ensuring greater fuel efficiency.

It can also be used for preparing marine surfaces for the anti-corrosion coatings which are essential for withstanding harsh saltwater environments.

Oil and gas

The oil and gas industry uses shot-blasting extensively across its infrastructure.

It’s a vital technique for the preparation of pipelines, removing dust and debris, and ensuring a clean surface for coating.

The interior of gas and oil storage tanks are extensively shot-blasted to help maintain the integrity of their infrastructure.

Manufacturing

Shot-blasting is used widely across the manufacturing sector.

Components such as machinery parts, appliances, and tools are shot-blasted to create a defect-free finish. It’s also used to clean moulds and dies, enabling consistency and precision in high-volume production. Shot-blasting also enables manufacturers to adhere to strict quality standards while improving the durability of their products.

Railways

Railway tracks are exposed to the elements and placed under high degrees of stress.

Shot-blasting removes rust and prepares them for welding, repair, and protective coatings.

To refurbish rolling stock, train carriages and components will often be shot-blasted to strip off old paint and rust before they are re-coated again.

Electronics

Shot-blasting has a range of specialised applications in the electronics industry.

Small components and casings can be shot-blasted to remove burrs, and to ensure smooth surfaces.

It’s also used to create fine surface textures on parts, such as connectors and heat sinks, to improve their functionality.

Components that require conductive or insulating coatings may be shot-blasted to help with adhesion.

Professional shot blasting services from Pershore Dip Coating

At Pershore Dip Coating, we provide a professional shot-blasting service that delivers exceptional results for our clients.

We pride ourselves on the quality of our work, and offer expert advice about the shot-blasting process.

Our collection and delivery service is available for clients within a 60-mile radius of our Worcestershire base.

Contact us to find out more about shot-blasting or to request a free quote.