Powder coating is a fantastic alternative to traditional paints. It offers many of the same strengths with some unique benefits over liquid paint.

Here we break down the powder coating process, what is powder coating, explaining how it works and why you want to consider it as a strong choice for your next coating job.

What is powder coating?

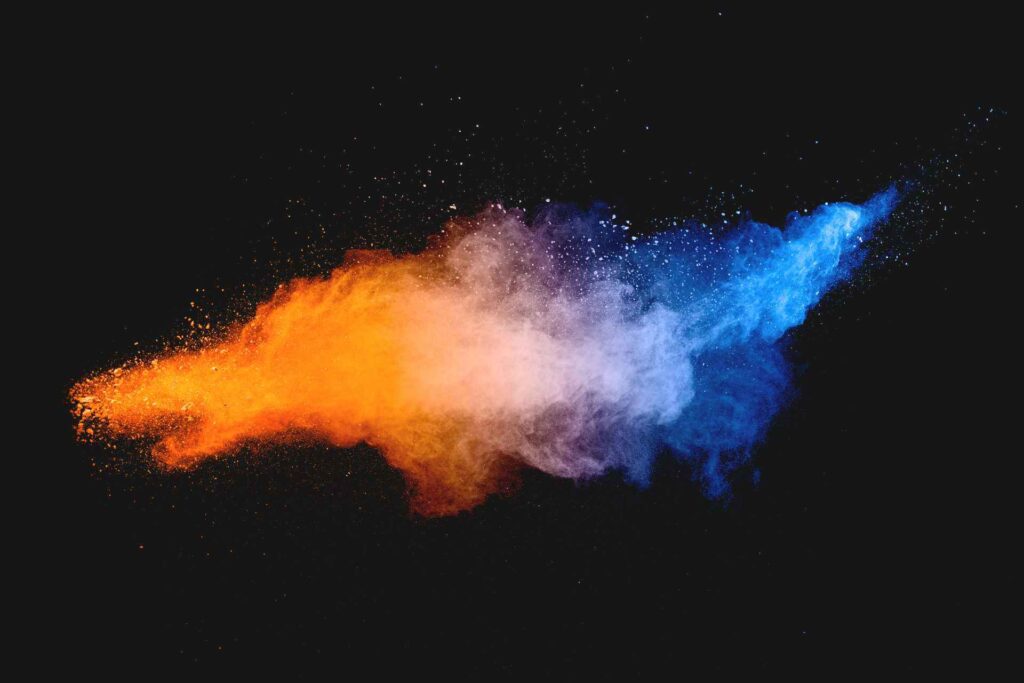

Powder coating is a dry finishing method. The powder itself is composed of polymers, either thermoplastic or thermoset, which are applied without any use of carrier fluid.

A powder coating is sprayed onto a part (the ‘substrate’) with an applied electrostatic charge. This makes the powder cling to the grounded substrate, and the powder is then cured using heat or UV light. This makes the particles melt and form a uniform coating, similar to that of liquid paint but stronger and much more stable.

Due to the need for static, powder coating’s use is mostly reserved for metal parts.

Why use powder coating?

Using powder coating grants numerous benefits that you don’t get with liquid paint.

Primarily, it uses no solvents and little to no organic volatile compounds (VOCs) which are off-gassed by liquid paint as it dries. These harmful chemicals are strongly scented and can be harmful when inhaled.

This also makes powder coatings safer to use in the long-term, as they are far less likely to chip and deposit in local soil as the coating ages.

Powder coats can be set with varying textural finishes. Apart from granting some aesthetic choice, this also allows a powder coating to grant some useful benefits such as added grip to handrails or abrasion resistance to objects being used in high-impact environments.

Using powder coating over paint is generally a cleaner, quicker, and more versatile way to coat objects and protect them for many years. It needs only some light maintenance to stay at its best for a long, long time.

How does powder coating work?

Powder coating is applied to a substrate and cured using heat or UV, which sets it as a uniform coat much like dried paint. Though it’s harder to apply properly than liquid paint, its outstanding resilience and aesthetic appeal makes it the better long-term option for many industries and uses.

The two kinds of polymers used in powder coating, thermoplastic and thermoset, behave slightly differently when cured. Thermoplastic powders can be reheated after the initial cure, making them more suited for reuse and recycling.

Thermoset powders, on the other hand, bond to the substrate when cured and cannot be reheated into a liquid state. For this reason, they’re generally hardier and stronger.

Different kinds of powder such as epoxies and polyesters have their own advantages and drawbacks to consider, too. Some are better for outdoors applications than others, or may have better resistance to abrasion, heat, and chemicals.

What are the steps for powder coating?

First, the substrate to be coated is prepared. This involves a thorough clean of the object, ensuring that there are no traces of dirt and grime, oils, or any previous finishes that might affect the powder’s ability to cling or the metal’s ability to be heated cleanly.

Next, the powder is applied to the substrate by use of a spray gun that applies an electrostatic charge to the particles. This causes the powder to cling to the substrate. Being a dry medium, any powder that fails to cling can be gathered and reused.

Once the powder has been thoroughly applied, it needs to be cured. This is typically done with the use of ovens that can heat the powder to the right temperature and for the right length of time. The specifics of these factors are known as the cure cycle, which may differ from one job to another.

Once cured and ready, all that’s left is maintenance of the coating to ensure it lasts as long as possible. The coating can often be cleaned using mild detergents without the need for topping up, as long as it hasn’t been left in an unsuitable environment.

When first looking into having a powder coating job done, your provider should be able to advise on the best type of coating for your specific goals.

How do I get a powder coating?

At Pershore Dip Coating, we’re experts in the powder coating process. Whatever you need coloured and protected for years to come, we can help.

To find out more about powder coating and what we can do for you, contact us today.